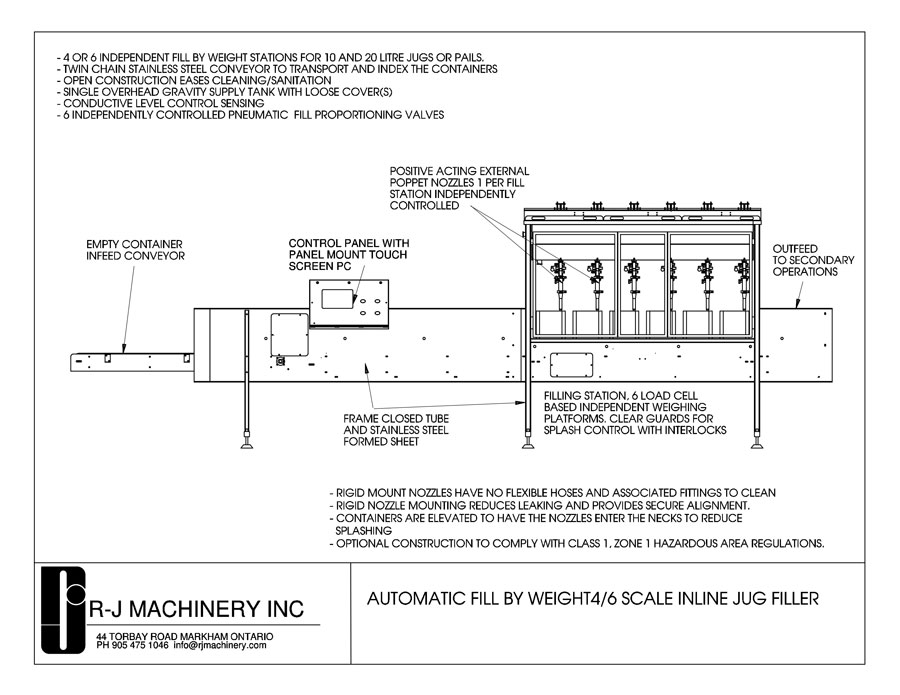

FBW Automatic Jug Filling

|

FBW Fill-By-Weight Automatic 6 Nozzle 10 & 20 Litre Jug Filler

|

R-J Model FBW-E6A Automatic Fill-By-Weight System to fill 10 & 20 litre plastic jugs. System is designed to operate in a localized Class 1 Division Hazardous Environment and is equipped as follows: 1 X Stainless Steel floor stand with leveling pads will support & integrate the 24 foot twin chain indexing conveyor with transfer lugs, load cell based filling platforms support stand for the overhead 200 litre hopper. 1 X 200 litre capacity Type 304 Stainless Steel overhead hopper with 6 x 1 1/2” Triclamp outlets.

6 X R-J Model QT-XP External poppet style 1” OD positive acting shut-off nozzles with 1 1/2” Triclamp connections. Rigid stainless steel tubing will connect the nozzle to the FRV Flow Restrictor Valve mounted inside the overhead hopper. The nozzles are Stainless Steel with Viton elastomer seals. There is no flexible tubing between the overhead tank & nozzle 6 X 50 lb capacity Tedea Load Cells with Stainless Steel enclosures. A Pneumatic elevating ramp will lift the 6 jugs off the transfer conveyor chain to have the jugs positioned on the load cell based weighing/filling stations. As the containers are elevated the fixed nozzles enter the container necks for the filling cycle. After the fill cycle the 6 containers will be lowered down to the lugged twin chain conveyor for transfer to secondary operations. 1 X Control circuit to be mounted into a NEMA 4 enclosure with the following features:

|