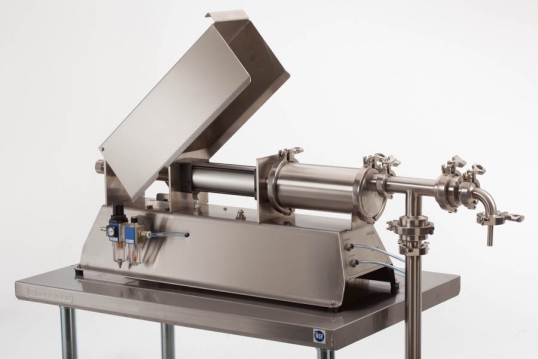

SDS-1000 Sanitary Design Series 1 litre Piston Filler

Innovative Solutions for Filling Applications

- Rugged Stainless Steel construction to resist corrosive products and cleaning/sanitizing chemicals. The pump assembly is mounted onto a formed stainless base with a hinged Stainless Steel cover leaving a smooth, easy to clean, corrosion resistant surface.

- Unique frame & cabinet design elements simplify maintenance and teardown procedures.

- Product contact parts Type 316 Stainless Steel, UHMW & Food Approved elastomers.

- The SDS-1000 will look great after years of service in the most hostile environments.

- FAST Tool Free Teardown Triclamps hold the complete metering pump together.

- Pump & piston assembly can be removed from the pump drive without any spills.

- Minimize product loss & reduce use of cleaning solutions.

- The pump contact parts are easy to handle to facilitate cleaning & sanitizing procedures.

- No more small nuts, bolts or screws down the drain or lost somewhere in your product.

- Triclamp Inlet connection for secure coupling to the bulk infeed supply or overhead hopper

- Powerful suction to draw product directly from low level tanks, drums or totes.

- Direct coupling to process vessels means a minimal amount of product handling and reduces exposure to risk of product contamination

- No need for overhead hoppers and transfer pumps for many applications

Interchangeable Pump heads & Nozzle assemblies:

- The ultimate in versatility. One common pump drive enables filling a wide variety of flowable products. Thin liquids to pastes & products with solid inclusions can all be filled with the same machine

- Fast changeovers from one style of product to another.